Sliding Gate Plate Inserts

We Are Dead Serious

About Your Business

FunMeet Solutions

We have developed and produced one kind of new type ceramic thermal Field

Improve With FunMeet

Saving 40-50% energy cost

FunMeet And Growth

Super long working life and anti-stripping performance,

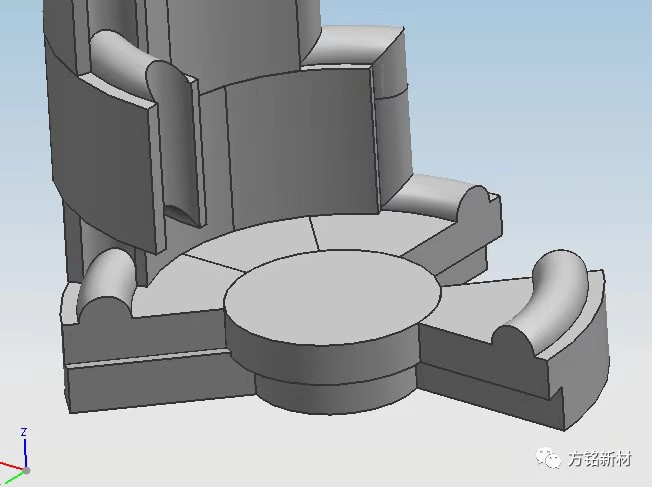

With the material technology continuous development, ladle slide plate, tundish slide plat converter taphole slag-stopping slide plate have been more and more frequently used in the modern smelting steel process. Through special technology optimization, Fangming New Material made continuously researching and testing, successfully produced PMO1 series of higher performance Zro2 composite ceramic Slide Plate, Ring, Insert. They have stronger crushing, erosion and thermal shock resisting, higher wearing resisting, embedded in the Al203-c(Corundum castable )body, as one kind of new type composite slide plate used in China large special steel plants, the max working time of converter slide plate is 28 times, the max one of ladle slide plate is 8 times.

PMO1 Series Zro2 Composite Ceramic Slide Plate, Zro2 Ring, Insert

Zirconia sliding plate has excellent mechanical strength, good wear resistance and erosion resistance; The manufacturing method of the high temperature resistant zirconia sliding plate is simple, the synthetic zirconia sliding plate has low impurity content and high product quality.

Incredible Numbers

We design and produce composite thermal field for Kyropoulos Way 120kgs Sapphire Ingot by ourselves.

Service life

Super long service life of up to three years

Save energy

18,000 degrees of energy saving per seeding of 1g of crystals

High temperature resistance

Long working temperature of YZO-ZrO2 series products is 2370-2650℃ in the air,Water vapor, nitrogen and vacuum environments.