2015Year

Date Of Establishment

16+

Soft Certification Qualification

12,000m²

Area

40+

Patent

Zhengzhou Fangming High-Temperature Ceramic New Material Co., Ltd. was established in 2015. It is a limited liability company initiated and established by a natural person with a registered capital of 10 million yuan. The industrial field is the field of new materials. The unified social credit identification code is 91410183356181033L. The State Key Laboratory of Wuhan University of Science and Technology, Shaanxi University of Science and Technology, Henan Institute of Technology and other institutions have established long-term industry-university-research cooperation.

The company covers an area of more than 12,000 square meters, the total number of employees is more than 55, more than 400 sets (sets) of various equipment, with an annual output of about 20,000 tons of high-purity and ultra-high temperature new composite nano-ceramic materials and products, which is recommended by the country in the Made in China 2025 planning catalog. And in the key new material category, high-tech production enterprises of rare earth composite new materials used in extreme environment ultra-high temperature structural ceramics that urgently need to breakthrough key technologies. The main business is the research and development, production and sales of nano-zirconia materials and products; import and export services of goods and technologies.

It owns more than 40 patents and has obtained 2 scientific and technological achievements appraisal certificates in Henan Province. It is the leading innovation team enterprise of Zhengzhou City 1125 Jucai Plan. In the past two years, it has completed and passed more than 16 soft certification qualifications (including Henan provincial special Jingtexin Enterprise Storage Qualification, National High-tech Enterprise Qualification, Zhengzhou Intelligent Manufacturing Demonstration Enterprise Qualification, Safety Production Standardization Qualification, Double Prevention Qualification, Quality, Health, Environment, Energy Management System Qualification, Integrity Management System Qualification, 5A Good standardization qualification, integration qualification of industrialization and industrialization, qualification of intellectual property management system, etc.).

The company mainly develops and manufactures ultra-high temperature and high-purity composite ceramic products based on oxide nano materials. The product state is nano, micron powder, granular materials and various ultra-high temperature special-shaped structure ceramics used in extreme environments; application temperature field It is an environment of 0 degrees Celsius to 2700 degrees Celsius, the application environment is: air, vacuum, protective atmosphere, etc. The application fields are high temperature melt flow control, special glass manufacturing, artificial crystals, laser crystals, semiconductor material growth, mobile phone glass cover 3D bending, The smelting of titanium alloys, etc.; the performance indicators of the series of high-purity zirconia insert products rank first in the domestic industry; the quality and technology of the series of products produced by the company is internationally leading, and it has successfully replaced Germany and the United Kingdom in markets such as India and Russia. Wait for the application of European products.

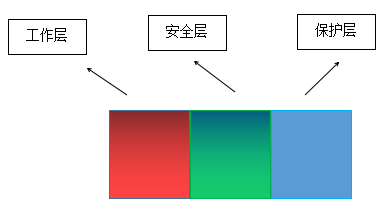

The idea of the new type of high-zirconium ceramic multifunctional composite brick is based on the shortcomings of current fused high-zirconium bricks such as corrosion resistance and erosion resistance, large kiln construction volume, high energy consumption and other shortcomings, using an integrated combination of three layers of different materials It has the characteristics of cutting processability and integrated sintering interface fusion. It has good thermal insulation, low gradient thermal stress, and different properties of corrosion resistance and erosion resistance of the working layer in contact with the glass solution. It is divided into three-layer combinations, which are working Layer, safety layer and insulation layer.

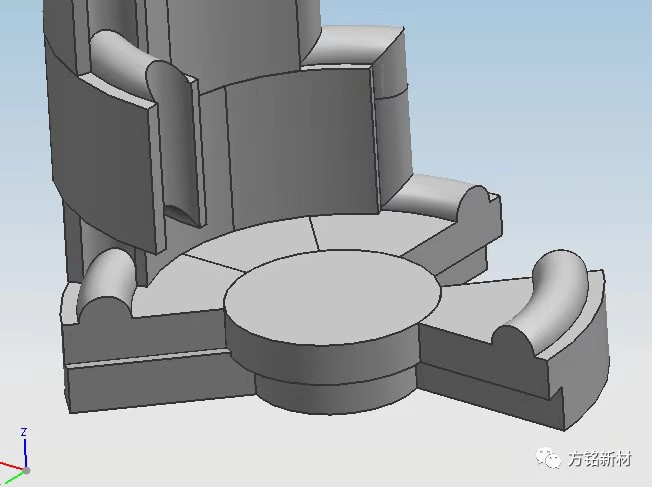

It is preset that the thickness of the insulation layer is 150 mm, the thickness of the safety layer is 150 mm, and the thickness of the working layer is 20-80 mm, which can be adjusted according to user needs.

Schematic diagram of high zirconium ceramic multifunctional composite brick structure

Adopt three layers of different materials to separate and bond into an integrated combination method, and use gradient composite technology for two or more materials to make the composition and structure change continuously from one side to the other side to reduce Small and overcome the performance mismatch phenomenon of the bonding part, to achieve the disappearance of the internal interface, the performance of the material also presents a gradient change corresponding to the change of the composition and structure.

The working layer adopts zirconium-based solid solution materials to avoid the defects of stable zirconium stabilization rate aging and decay. The combination of micron and nanometer powders has zirconium content ranging from 80-94%, achieving sintering 99% densification, and porosity close to 0. The temperature resistance reaches 1750 degrees Celsius for the purpose of long-term use, in order to deal with the long-term constant glass solution erosion and scouring conditions of the working layer, and is committed to achieving 2 times or more than the life of the current 41# fused brick.

The protective layer is made of high-purity alumina raw materials or zirconium silicate. Its function is reflected in the long-term use safety guarantee after the working layer. At the same time, it has a good thermal gradient reduction function.

The insulation layer is made of fiber materials that can withstand temperatures up to 1650 degrees Celsius, and its thermal conductivity is low. When the design thickness is used at 100-150 mm, when the heating temperature reaches 1400 degrees Celsius, the surface temperature is lower than 60 degrees Celsius. (Optional according to the situation)

According to different types of glass, according to its characteristics, you can choose:

01

Calcium zirconate solid solution (use temperature 0-1720℃, melting point 2250-2550℃, density 5.11 g/(25 ℃))

02

Barium zirconate solid solution (use temperature 0-1720°C, melting point: 2500°C, density: 5.52g/ml (25°C))

03

Yttrium-zirconium solid solution (use temperature 0-1720℃, melting point: 2850℃, density: 4.80g/ml (25 ℃))

Wait for the targeted use of the above products to promote them to reduce interface damage caused by chemical reactions at high temperatures, thereby improving the service life and the safety of glass products. Therefore, compared with traditional materials, targeted application of materials to promote the increase of life It is also one of the very effective methods.

The application temperature range is 0 degrees Celsius to 2700 degrees Celsius, the application environment is: air, vacuum, protective atmosphere, etc., the application fields are special glass manufacturing, titanium alloy smelting, etc.;

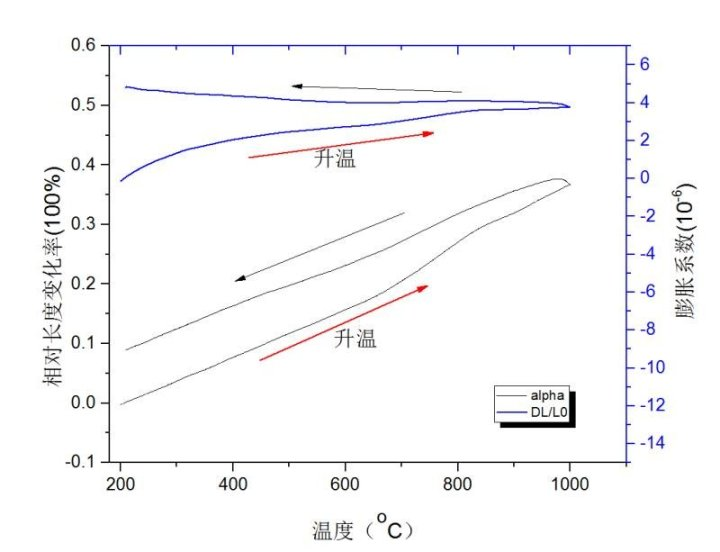

The splicing gap is 0.2-0.5 mm, and it can be used as a gap bonding scheme. The linear expansion rate of 0-1000℃ is 5.5×10-6,0-1000℃ and the relative length change rate is 0.08%.

After the use temperature exceeds 1700°C, conventional high-zirconium materials can no longer meet the long-term use requirements after 1750°C due to their load softening, liquid phase precipitation, and active chemical reactions. After 1750°C, traditional high-zirconium materials are used. Materials such as AZS will accelerate damage and erosion. Therefore, stable high zirconium materials or solid solution materials must be used in the ultra-high temperature environment after 1750 ℃ to meet the conditions of long-term ultra-high temperature use and the conditions that are not easy to react with other active elements. When the temperature is higher than 1750°C for long-term contact with glass solutions or other metal solutions, the theoretical life of high zirconium materials with a temperature higher than 1800°C-2200°C can be increased by 2-3 times.

Without continuous innovation, there will be no vitality, and it will be impossible to compete for the commanding heights with European counterparts with a long history and strong scientific research foundation advantages on the world stage. Starting from the company's positioning in the field of ultra-high temperature structural ceramic new materials in 2015, the company Deeply carry out industry-university-research cooperation with many well-known domestic universities, give full play to its own subject advantages, and combine the research advantages of university industry-university-research to continuously innovate and continuously apply products to new fields. The company has 11 independent invention patents, which are practical 29 new patents.

Under the premise of leading the market with core technology, the company established a product application experience guarantee department to provide customers with a safe, effective and fast one-stop application experience, actively explore new product application problems and improve improvements, and provide customers with efficient and stable products At the same time of application experience, we will continuously improve the new level of product application.

Only in this way can customers have a sense of application dependence, application security, and application comfort. Only in this way, a virtuous circle can be formed, and the company's product market share and stability can continue. Enhance and strongly support the company’s continuous R&D and operation vitality; supported by the core technical force of continuous innovation, the company’s products currently have good comprehensive performance and experience. At the same time, they have a huge cost-effective advantage in international emerging markets. They have already competed with Germany and the United Kingdom. The market occupied by similar products in developed countries such as Japan and Japan has emerged.

Overview of the company’s development thinking and direction: Focusing on the field of zirconium dioxide materials and products, through the infinite recycling of resources through the green manufacturing system, focusing on the use of innovative research and development, innovative manufacturing methods, and innovative application fields in the field of zirconium dioxide materials and products,

To achieve continuous innovation and application-specific products and sustainable company vitality, establish brand awareness in the industry, and formulate the company's future development guidance on the basis of limited technology and experience precipitation and unlimited application fields and performance innovation!

Our Mission

Solve bottlenecks in ultra-high temperature applications

Corporate Vision

Become a benchmark enterprise in the sustainable development of ultra-high temperature structural ceramics industry

Value

Integrity, dream, hard work, innovation;