Zhengzhou Fangming High-Temperature Ceramics New Material Co., Ltd. developed two new slag blocking mechanism slides for converter slag: anti-metallic solution swirl slide and anti-inlaid body pressurized upper displacement slide, which obtained patent authorization.

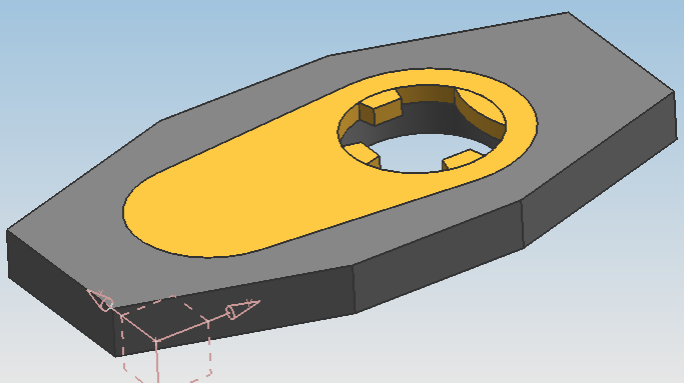

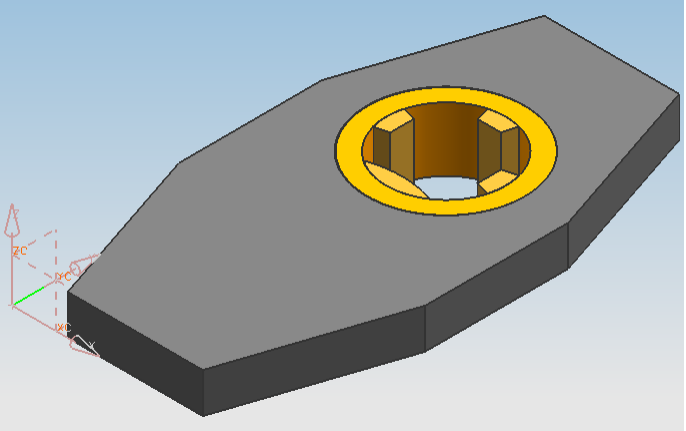

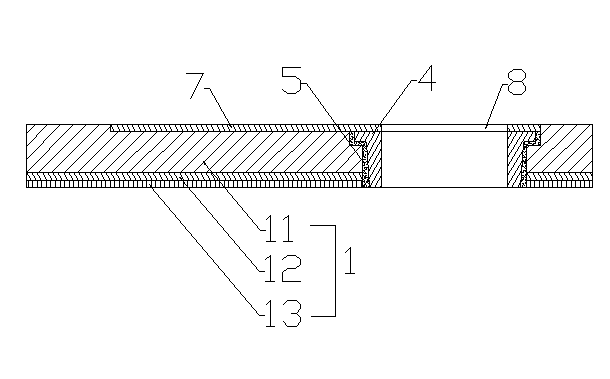

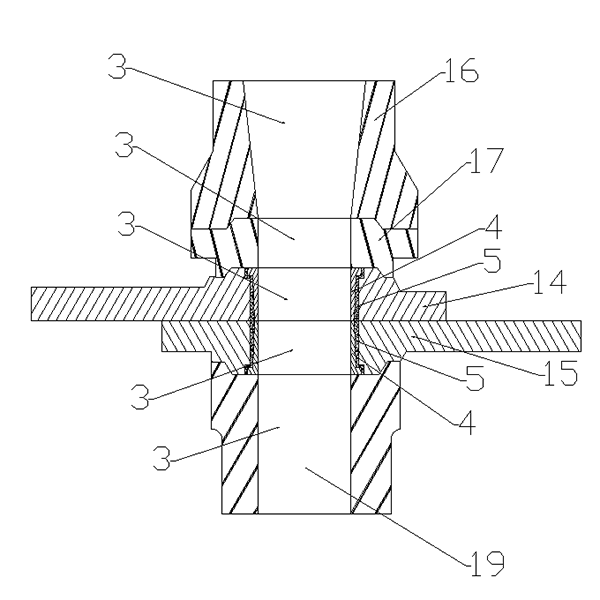

Anti-metallic solution swirling slide plate: The anti-swirl slide plate and channel of the converter slag stop mechanism include 5 bricks consisting of steel tap bricks, inner nozzle bricks, inner slide bricks (zirconia ceramics), outer slide bricks and outer nozzle bricks. Concave-convex connection is adopted between the bricks, the bottom plate, the refractory layer or the refractory inlay layer and the adhesive layer, the inner wall of the solution channel of the inner slide brick and the outer slide brick is designed as an irregular channel, showing a concave-convex shape, the inner slide brick The bonding plane with the outer skateboard brick is pressed by the external mechanism or bonded by using refractory bonding mud to achieve a seamless state. The external force mechanism pushes the upper and lower skateboard bricks to the channel by friction. Corresponding position, the solution passes; the design of this product can prevent the formation of a spiral solution caused by pressure when the solution passes between the upper and lower slide bricks, and force the regular spiral solution to be a downstream solution.

The solution channel irregular washing and the adhesion of the steel slag caused the upper and lower sliding plate bonding surface damage and the inner nozzle brick and the outer nozzle brick to suffer from the spiral solution damage. It has a good effect; it is done in the zirconium plate channel and the zirconium ring channel of the upper and lower sliding plate. Irregular bumps and bump column structures of different thicknesses are formed. When the molten steel passes through the upper and lower plate channels, due to the presence of the bump column structure, the swirling flow of the molten steel is inhibited, so that the molten steel can enter downstream through the upper and lower plates. The inner nozzle channel solves and reduces the phenomenon of steel clamping caused by the swirling solution on the upper and lower plates, and also has a significant inhibitory effect on the scouring of the connection between the inner nozzle and the upper and lower plates caused by the swirling solution, thereby simultaneously improving the inner The service life of the nozzle and the tapping port increases the overall service life, stability and safety of the upper and lower plates, the inner nozzle and the tapping port. Secondly, the irregular concave-convex design of ceramic embedded in the slide brick channel can be designed arbitrarily, and it is not restricted by the shape under the premise of ensuring the throughput of the solution, which improves the current continuous large-scale production demand in smelting, purification, metallurgy and other industries.

(A) Anti-metallic solution swirling under the sliding plate

(B) Anti-metallic solution swirling on the sliding plate

Anti-metal solution swirling slide

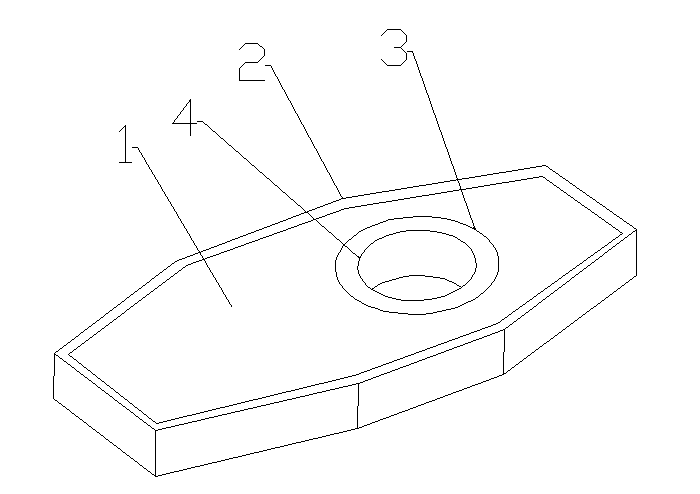

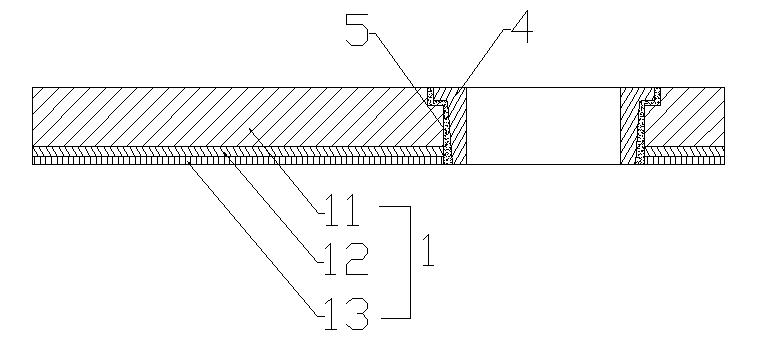

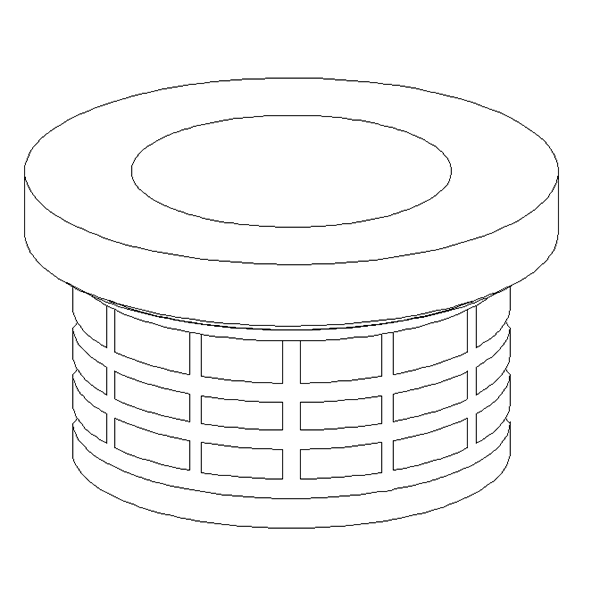

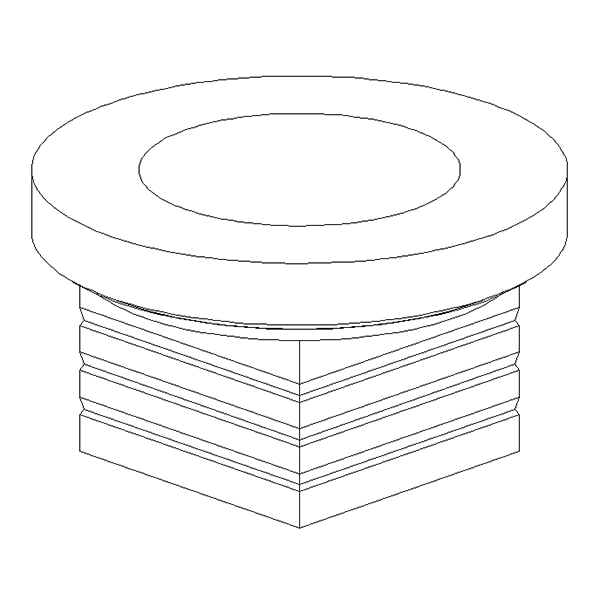

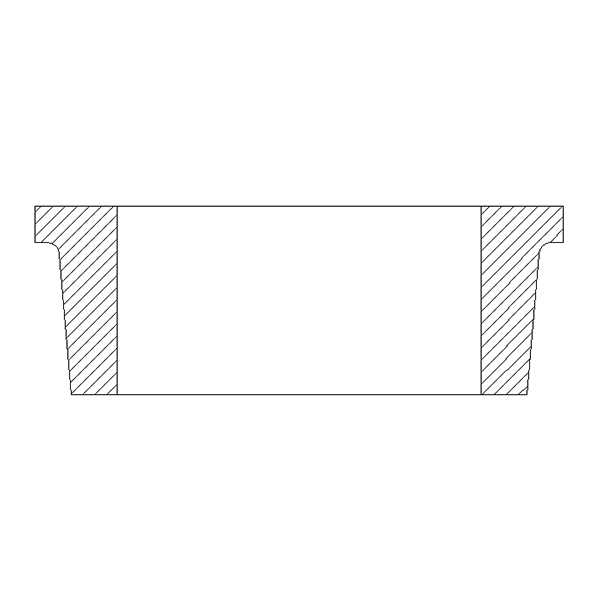

The upper displacement slide plate of the anti-inlaid body under pressure: the embedded anti-recession upper displacement ceramic inner core slide plate used on the converter slag stop mechanism includes a slide plate. The outer ring surface of the slide plate is equipped with clamping parts and the slide plate is provided with liquid The hole is provided with a ceramic inner core for circulating the solution. The ceramic inner core includes an inner core body. The outer wall of the inner core body is not smooth or irregular, and the top of the inner core body is circular and has a T-shaped boss extending outward , The center of the inner core body has a cylindrical through hole for circulating the solution. The slide plate includes a substrate, a heat insulation plate and a bottom plate that are sequentially bonded together from top to bottom. The embedded ceramic core for circulating the solution on the slide plate is designed as T-shaped integrated product structure, the outer circle can be designed as an irregular shape, which can effectively prevent the ceramic parts embedded in the upper slide plate from sinking and shifting due to the high surface pressure between the upper and lower slide plates at high temperatures, which greatly saves It saves resources, saves costs, increases the service life of the overall skateboard, and has strong safety and practicability.

(A) General sketch map of skateboard

(B) Side profile view of skateboard

(C) Side profile view of skateboard

(D) Embedded ceramic parts in the skateboard 1

(E) Embedded ceramic parts in the skateboard 2

(F) Embedded ceramic parts in the skateboard 3

(G) Schematic diagram of skateboard assembly

Zhengzhou Fangming High-Temperature Ceramic New Material Co., Ltd. has an annual output of about 20,000 tons of high-purity and ultra-high temperature new composite nano-ceramic materials and products. It is an application that urgently needs to break through key technologies in the new material category advocated and developed by the state in the Made in China 2025 planning catalog. A high-tech manufacturer of rare earth composite new materials for ultra-high temperature structural ceramics in extreme environments. The main business is the research and development, production and sales of nano-zirconia materials and products; import and export services of goods and technologies.

Post time: May-25-2021