8 Year Exporter High Temperature Cement Mix - Rare-EarthCompositeCeramicSmeltingCrucible – FunMeet

8 Year Exporter High Temperature Cement Mix - Rare-EarthCompositeCeramicSmeltingCrucible – FunMeet Detail:

We Are Dead Serious

About Your Business

FunMeet Solutions

We have developed and produced one kind of new type ceramic thermal Field

Improve With FunMeet

Saving 40-50% energy cost

FunMeet And Growth

Super long working life and anti-stripping performance,

Detail

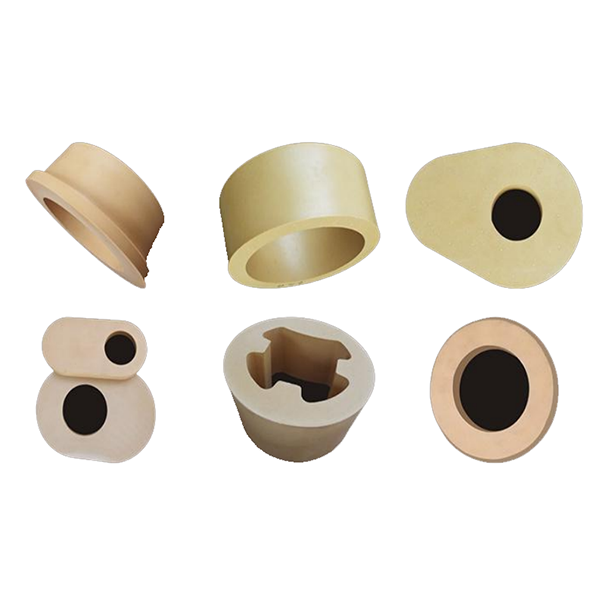

Rare Oxide Composite Ceramic Smelting Crucible

Ti-alloy material is the composed alloy of adding other element based on Ti. Ti and Ti- Alloys Products have strong strength, high smelting point, low density, excellent erosion and heat resistance, good mechanical properties, toughness, etc. features, then widely used in the aviation industry, as compressor component of aircraft engine, structure component of rocket, missile, high speed aeroplane, etc. industries.

Casting Technology of Ti- Alloy Products can reveal the industry strength of one country. The limited term of casting is low chemical reacted with other materials at under high-temp. Terms.When casting, it is necessary to adopt HP super Hi-Temp. Material,which could not be wetted and adhered with Ti and Ti- Alloy. HP Y203, HP Y203-Zr02 Solid Solution, HP Barium Zirconate, etc. Ceramic Materials can satisfy the exacting casting term for the Ti & Ti-Alloy products.

Their working temperature is from 1600-2300 deg.cel. Do not adhere and wet with Ti& Ti- Alloy metal liquids.Excellent chemical stability and crushing resistance. It is the ideal new type material of casting metal Ti&Ti-Alloy, Precious Metal melting and casting industries.

Using the slope of the side wall, the crucible is very convenient to pour the molten metal in it, and the smooth arc bottom makes the metal in it basically reach the same temperature. Therefore, the crucible can save melting time.

Incredible Numbers

We design and produce composite thermal field for Kyropoulos Way 120kgs Sapphire Ingot by ourselves.

1,095

Service life

Super long service life of up to three years

18,000

Save energy

18,000 degrees of energy saving per seeding of 1g of crystals

2,650

High temperature resistance

Long working temperature of YZO-ZrO2 series products is 2370-2650℃ in the air,Water vapor, nitrogen and vacuum environments.

Ready for a new

Business Adventure?

Product detail pictures:

Related Product Guide:

We now have our individual sales group, layout team, technical team, QC crew and package group. Now we have strict high-quality control procedures for each procedure. Also, all of our workers are experienced in printing discipline for 8 Year Exporter High Temperature Cement Mix - Rare-EarthCompositeCeramicSmeltingCrucible – FunMeet , The product will supply to all over the world, such as: Barcelona, Lahore, South Korea, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality products. Our business aims to "honest and trustworthy, favorable price, customer first", so we won the trust of the majority of customers! If you are interested in our products and services, please do not hesitate to contact us!

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!