Sliding Gate Plate Inserts

We Are Dead Serious

About Your Business

FunMeet Solutions

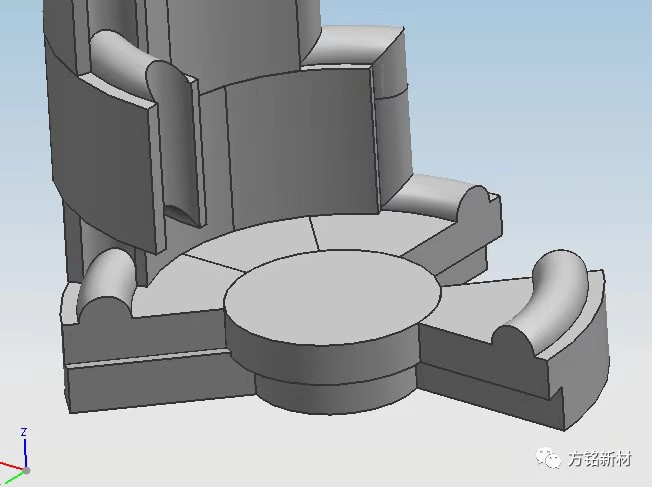

We have developed and produced one kind of new type ceramic thermal Field

Improve With FunMeet

Saving 40-50% energy cost

FunMeet And Growth

Super long working life and anti-stripping performance,

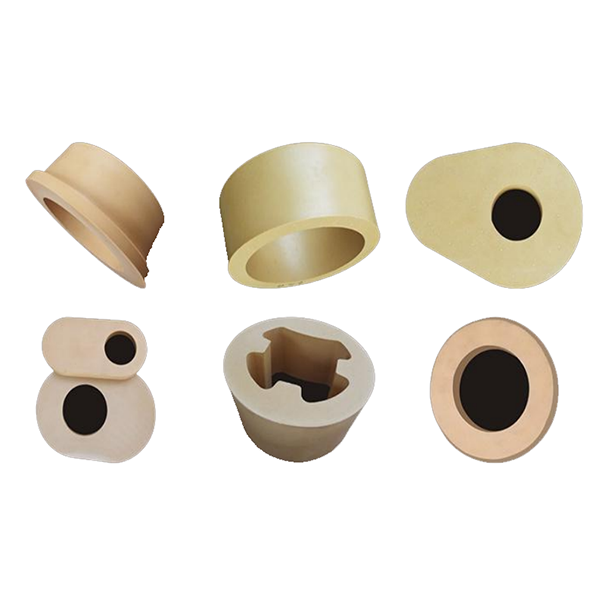

MO1& PMD Promoted Zro2 Slide Gate Plate, Ring, Inset.

Our HP& HD PMO1&PMD products have high purity and density, excellent crush, erosion resistance and thermal shock stability, increase the working times of slige gate plates and accessory products.

In order to improve the product quality of ZrO2 sliding plate containing MgO and improve its service life on converter, the microstructure photos with magnification of 10000 ~ 100000 times were taken. The microstructure and corrosion mechanism of the product before and after use were investigated by fesem-eds. the results show that the main crystal phases are strip woven c-ZrO2 and granular m-ZrO2 crystal, A small amount of M2S and other cemented phases are generated between the crystals. The used sliding plate has a segmental structure. The eutectoid phase transformation of ZrO2 occurs in the reaction zone and a series of reaction products are generated, such as CaZrO3, FeO, spinel, silicate, etc. the damage of the sliding plate is mainly the erosion of slag.

Different steel types, different working temp. of steel liquid, different liquid flowing amount and speeds will influence of working lives of slide gate plate.

In view of the shortcomings of ordinary aluminum carbon sliding plate, such as low strength, poor corrosion resistance and poor thermal shock resistance, experimental research is carried out from the aspects of material, micro powder additives and production technology. Based on ordinary aluminum carbon sliding plate, an aluminum carbon zirconium composite sliding plate with excellent performance is developed, which meets the service requirements of continuous casting 160t ladle for three times at Pangang.

Adopt composite slide gate plate with embedded our HP&HD Zro2 inserts is the direction and mainstream of steel-melting development with converter in the future.

Incredible Numbers

We design and produce composite thermal field for Kyropoulos Way 120kgs Sapphire Ingot by ourselves.

Service life

Super long service life of up to three years

Save energy

18,000 degrees of energy saving per seeding of 1g of crystals

High temperature resistance

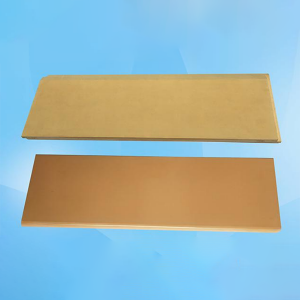

Long working temperature of YZO-ZrO2 series products is 2370-2650℃ in the air,Water vapor, nitrogen and vacuum environments.