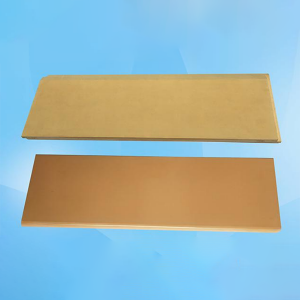

Cover plate and lip brick of high zirconium photovoltaic glass and shale glass

Contact Us

Detail

Solar glass is mainly used for solar photovoltaic power generation and Ultra white calendered glass for packaging or cover plate of solar photo thermal module.The rapid growth of solar cells has brought a big boost to the glass industry Promising market demand. Fierce competition in ordinary glass Market Strong, the profit margin is not satisfactory, the solar glass is high The return is consistent with the loss situation in the domestic flat glass original sheet market for many years .In recent years, more and more flat glass manufacturers have joined in. Multiple glass Manufacturers have invested a lot of money in the production and R & D of different types of and Excellent photovoltaic glass products.

The innovation of multi-point temperature control technology ensures the fine control of temperature system.Key factors affecting glass liquid flow in the production of new solar photovoltaic glass (ultra white glass).The company finally adopts a separate hot spot arch top temperature as the standard point for control according to The change law, influence degree and temperature of each temperature point are explored According to the relationship between points during change, the correction factor is accurately given and brought into the control system, that is It effectively ensures the fine control of temperature system under normal operating conditions, and also ensures the production. The key temperature points of the furnace are relatively stable in the production process.