Discount Price Mullite Melting Point - ArtificialCrystalGrower-Rare-EarthCompositeCeramicThermalField – FunMeet

Discount Price Mullite Melting Point - ArtificialCrystalGrower-Rare-EarthCompositeCeramicThermalField – FunMeet Detail:

Detail

Rare Oxide Composite SS Ceramic Thermal Field

Synthetic Crystal is one kind of important crystals in military and civilian application.

Up to now, whole world’ S Synthetic Crystal enterprises have used metal, ZrO2 Fiber, dense ZrO2 brick etc. quality thermal fields. The sapphire ingot polluted, shrinkage, deformed, collapsed of thermal field, etc. problems arise.

Rare earth oxide (RE) doped yttria stabilized zirconia (YSZ) is one of the effective ways to improve the thermal insulation performance and high temperature stability of traditional YSZ thermal barrier coatings.

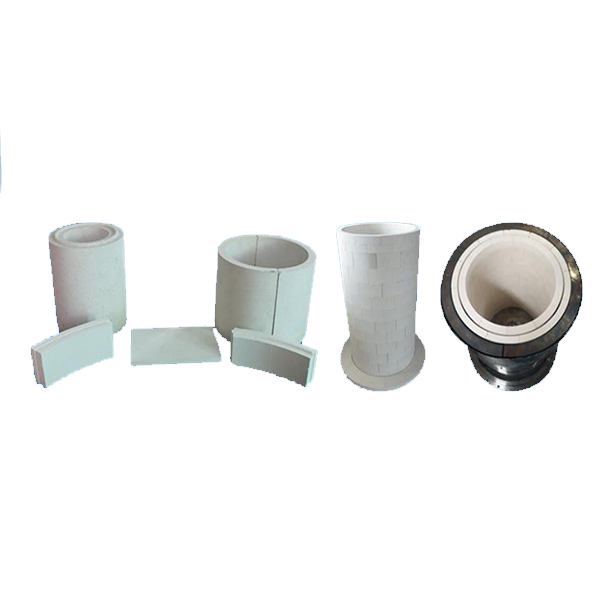

Trough constant R&D, improvement, successfully produced one of most advanced ceramic thermal field—Solid Solution Ceramic Composite Thermal Field. It have below obvious features:. Ultra Low-Deformation. Few Oxide Volatilization · Rapid Releasing Oxygen. Super Low Energy Cost. Long Working Life.

We design bi-layer composite thermal field. Inner is Hi- Temp. Resistant layer, Outer is Bubble ZrO2 polymer ball layer, protecting inner brick, also max insulating function, what’s for gradient stabilization of transverse temperature, meantime obviously saving the power consumption.

With the development of high-performance gas turbine, the inlet temperature of high-pressure turbine continues to increase, which brings a more severe service environment for hot end components such as combustion chamber, blade and tail nozzle. Ordinary high-temperature metal alloy has been difficult to meet the service requirements. In recent years, thermal barrier coating has been widely used. At present, it is the most widely used yttria stabilized zirconia (YSZ) thermal barrier coating ceramic material. Due to the problems of temperature phase transformation, sintering acceleration, high temperature radiation heat transfer and molten salt corrosion at high temperature, its further application is limited.

We design and produce composite thermal field for Kyropoulos Way 120kgs Sapphire Ingot by ourselves. Upon ensuring rate of 100% finished product, the seeding power has successfully bring downto 59KW from 75KW. Now normally saving power per furnace is 10000 deg, even can reach 1 5000-18000deg.

Product detail pictures:

Related Product Guide:

abide by the contract", conforms into the market requirement, joins in the market competition by its good quality also as provides a lot more comprehensive and great company for purchasers to let them turn into huge winner. The pursue from the firm, would be the clients' gratification for Discount Price Mullite Melting Point - ArtificialCrystalGrower-Rare-EarthCompositeCeramicThermalField – FunMeet , The product will supply to all over the world, such as: Doha, Leicester, USA, We welcome you to visit our company & factory and our showroom displays various products and solutions that will meet your expectations. Meanwhile, it is convenient to visit our website. Our sales staff will try their best to supply you with the best services. If you will need more information, please do not hesitate to contact us via E-mail, fax or telephone.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.