factory customized Custom Ceramic Products - ZirconiameteringNozzle(PMDQuality) – FunMeet

factory customized Custom Ceramic Products - ZirconiameteringNozzle(PMDQuality) – FunMeet Detail:

We Are Dead Serious

About Your Business

FunMeet Solutions

We have developed and produced one kind of new type ceramic thermal Field

Improve With FunMeet

Saving 40-50% energy cost

FunMeet And Growth

Super long working life and anti-stripping performance,

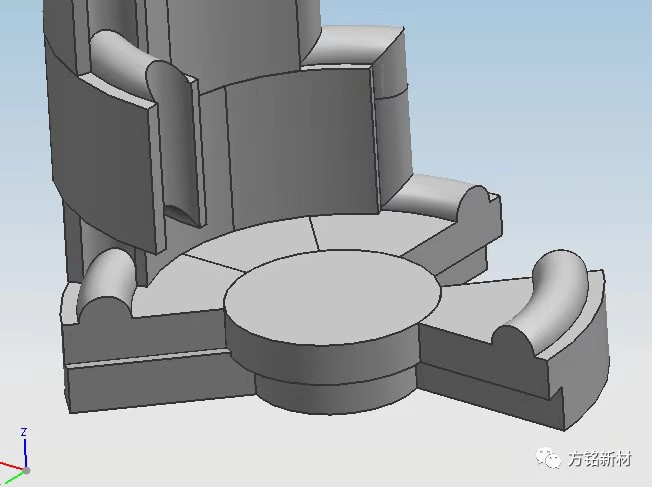

PMD Series of Zro2 composite ceramic tundish nozzle insert

The experimental results show that the PS based binder system has better strength, surface and smoothness when mixed at 125 ℃ for 10 min, and is less sensitive to temperature, which is more suitable for ceramic injection. On this basis, the powder bearing capacity is increased by 86%, To reduce the defects in the later degreasing and sintering process. Put the mixed feed in muffle furnace for degreasing, study the degradation temperature range of each component of binder by TG, and formulate the degreasing curve suitable for this system. Then burn at different temperatures, The degreasing and sintering surfaces were observed by TEM. The crystal phase changes of zirconia ceramics were investigated by XRD. The mechanical properties of zirconia ceramics at different temperatures were studied. The results show that the composite ceramics sintered at 1550 ℃ have better properties. The composite ceramics composed of alumina and zirconia with different contents were selected for degreasing and sintering. The structure and properties of the composite ceramics were studied by XRD and TEM, And it can reduce the cost of raw materials.

On the basis of PMO1 series of Zro2 composite ceramic products, through continuous special technology optimization, Fangming New Material successfully R&D, produced PMD series of higher performance Zro2 composite ceramic tundish nozzle inserts. They have higher purity, stronger crushing, erosion, thermal shock resisting, longer working life. Their theoretical working life is raised by 30-50% based on the PMO1 series of products at the same working condition.

Incredible Numbers

We design and produce composite thermal field for Kyropoulos Way 120kgs Sapphire Ingot by ourselves.

1,095

Service life

Super long service life of up to three years

18,000

Save energy

18,000 degrees of energy saving per seeding of 1g of crystals

2,650

High temperature resistance

Long working temperature of YZO-ZrO2 series products is 2370-2650℃ in the air,Water vapor, nitrogen and vacuum environments.

Ready for a new

Business Adventure?

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to deliver you with great provider of processing for factory customized Custom Ceramic Products - ZirconiameteringNozzle(PMDQuality) – FunMeet , The product will supply to all over the world, such as: Orlando, Poland, Hyderabad, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.