Factory directly Milling Ceramic Material - Rare-EarthCompositeCeramicSmeltingCrucible – FunMeet

Factory directly Milling Ceramic Material - Rare-EarthCompositeCeramicSmeltingCrucible – FunMeet Detail:

Detail

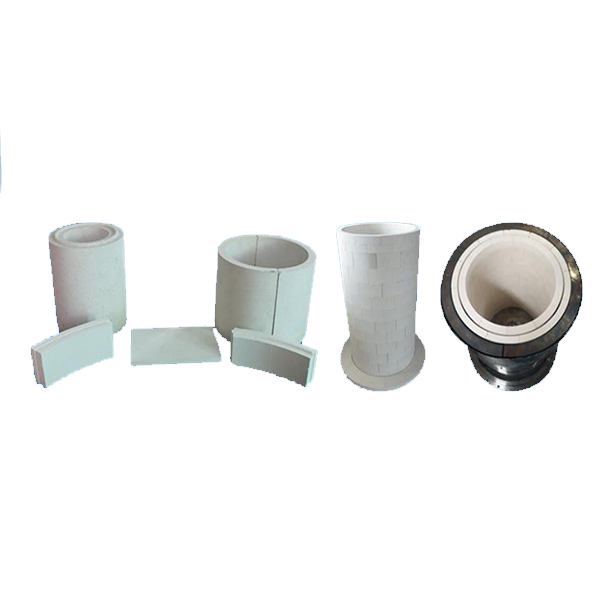

Rare Oxide Composite Ceramic Smelting Crucible

Ti-alloy material is the composed alloy of adding other element based on Ti. Ti and Ti- Alloys Products have strong strength, high smelting point, low density, excellent erosion and heat resistance, good mechanical properties, toughness, etc. features, then widely used in the aviation industry, as compressor component of aircraft engine, structure component of rocket, missile, high speed aeroplane, etc. industries.

Casting Technology of Ti- Alloy Products can reveal the industry strength of one country. The limited term of casting is low chemical reacted with other materials at under high-temp. Terms.When casting, it is necessary to adopt HP super Hi-Temp. Material,which could not be wetted and adhered with Ti and Ti- Alloy. HP Y203, HP Y203-Zr02 Solid Solution, HP Barium Zirconate, etc. Ceramic Materials can satisfy the exacting casting term for the Ti & Ti-Alloy products.

Their working temperature is from 1600-2300 deg.cel. Do not adhere and wet with Ti& Ti- Alloy metal liquids.Excellent chemical stability and crushing resistance. It is the ideal new type material of casting metal Ti&Ti-Alloy, Precious Metal melting and casting industries.

Using the slope of the side wall, the crucible is very convenient to pour the molten metal in it, and the smooth arc bottom makes the metal in it basically reach the same temperature. Therefore, the crucible can save melting time.

Product detail pictures:

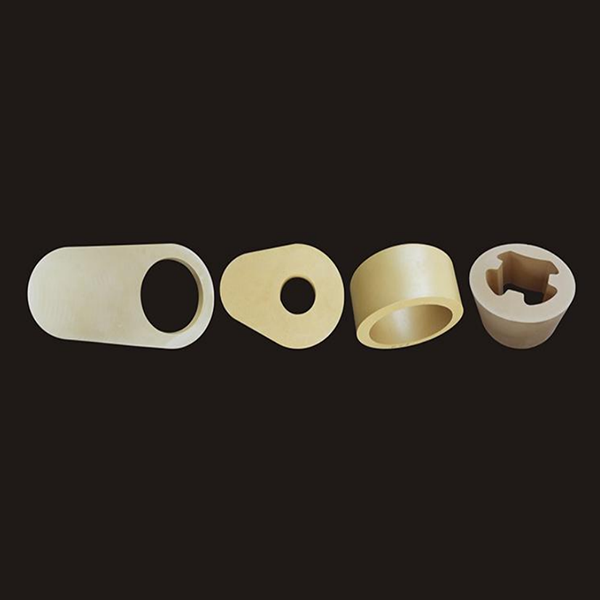

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our management ideal for Factory directly Milling Ceramic Material - Rare-EarthCompositeCeramicSmeltingCrucible – FunMeet , The product will supply to all over the world, such as: Tunisia, Tanzania, Sao Paulo, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.