High Quality for Ceramic Implants - ZirconiameteringNozzle(PMDQuality) – FunMeet

High Quality for Ceramic Implants - ZirconiameteringNozzle(PMDQuality) – FunMeet Detail:

Detail

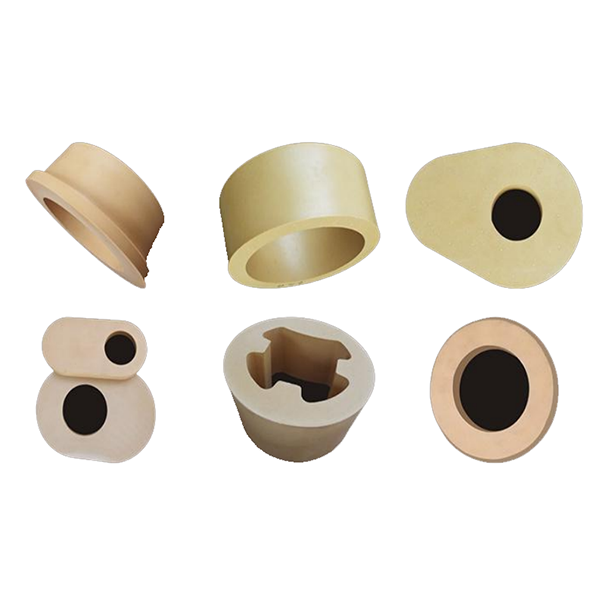

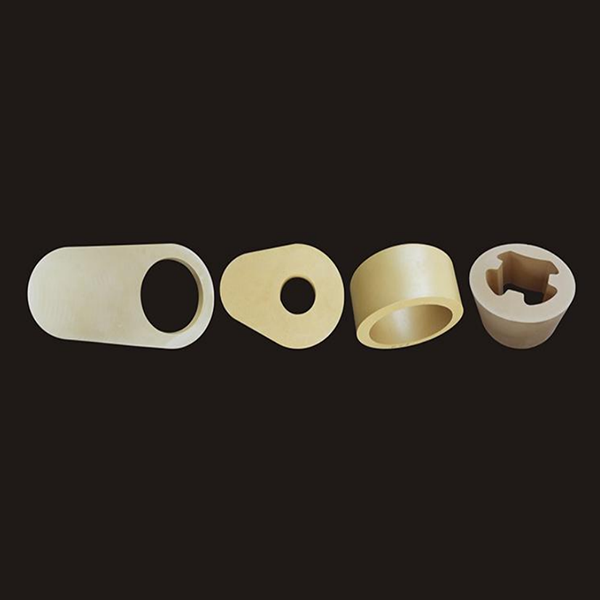

PMD Series of Zro2 composite ceramic tundish nozzle insert

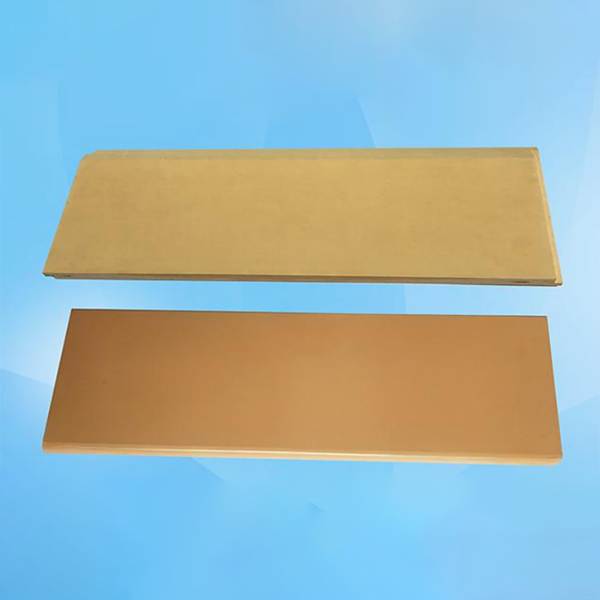

The experimental results show that the PS based binder system has better strength, surface and smoothness when mixed at 125 ℃ for 10 min, and is less sensitive to temperature, which is more suitable for ceramic injection. On this basis, the powder bearing capacity is increased by 86%, To reduce the defects in the later degreasing and sintering process. Put the mixed feed in muffle furnace for degreasing, study the degradation temperature range of each component of binder by TG, and formulate the degreasing curve suitable for this system. Then burn at different temperatures, The degreasing and sintering surfaces were observed by TEM. The crystal phase changes of zirconia ceramics were investigated by XRD. The mechanical properties of zirconia ceramics at different temperatures were studied. The results show that the composite ceramics sintered at 1550 ℃ have better properties. The composite ceramics composed of alumina and zirconia with different contents were selected for degreasing and sintering. The structure and properties of the composite ceramics were studied by XRD and TEM, And it can reduce the cost of raw materials.

On the basis of PMO1 series of Zro2 composite ceramic products, through continuous special technology optimization, Fangming New Material successfully R&D, produced PMD series of higher performance Zro2 composite ceramic tundish nozzle inserts. They have higher purity, stronger crushing, erosion, thermal shock resisting, longer working life. Their theoretical working life is raised by 30-50% based on the PMO1 series of products at the same working condition.

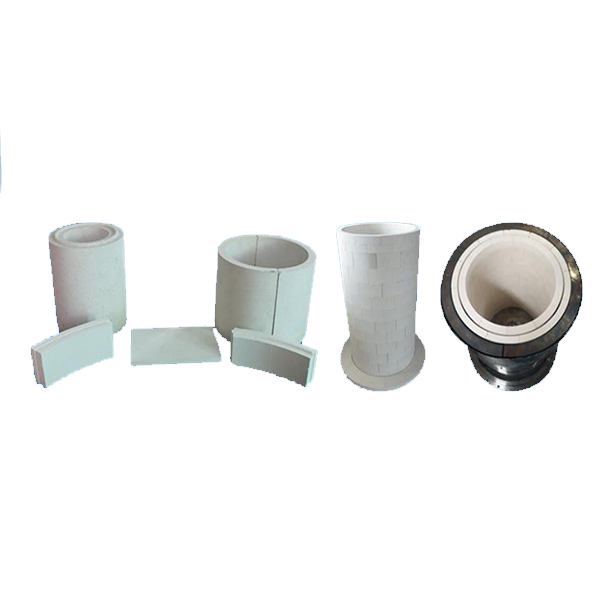

Product detail pictures:

Related Product Guide:

Our advancement depends over the highly developed devices, excellent talents and continually strengthened technology forces for High Quality for Ceramic Implants - ZirconiameteringNozzle(PMDQuality) – FunMeet , The product will supply to all over the world, such as: Vietnam, Madras, Jeddah, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question items they do not understand. We break down people barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

A good manufacturers, we have cooperated twice, good quality and good service attitude.