Hot sale Zenostar Zirconia - Metal Powder/Ti Series Powder Sintering Gasket – FunMeet

Hot sale Zenostar Zirconia - Metal Powder/Ti Series Powder Sintering Gasket – FunMeet Detail:

We Are Dead Serious

About Your Business

FunMeet Solutions

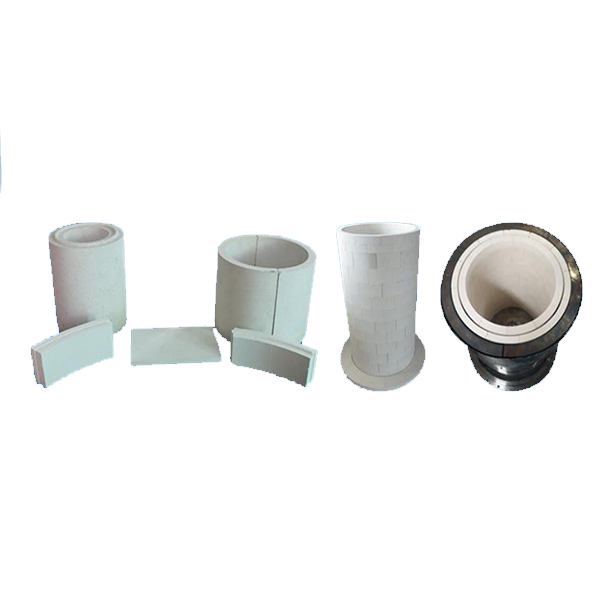

We have developed and produced one kind of new type ceramic thermal Field

Improve With FunMeet

Saving 40-50% energy cost

FunMeet And Growth

Super long working life and anti-stripping performance,

Electronic Component substrates

Our products are taking super high temperature composite ceramic raw material, through scientific grain gradation, mixing and grinding ,vibrating pressing, high temp. sintering etc. advanced technology and process finished. They have high-temp resisting,stable chemical performance, excellent thermal shock stability, non- wetting and adhered, easy operating, longer-working life etc. Features. Y203-ZrO2 composite and HP Y2O3 ceramic qualities are what we are usually supplying.

Application

1.Capacitor etc. Electronic component substrate sintered.

2.Barium Titanate,Magnetic material sintered.

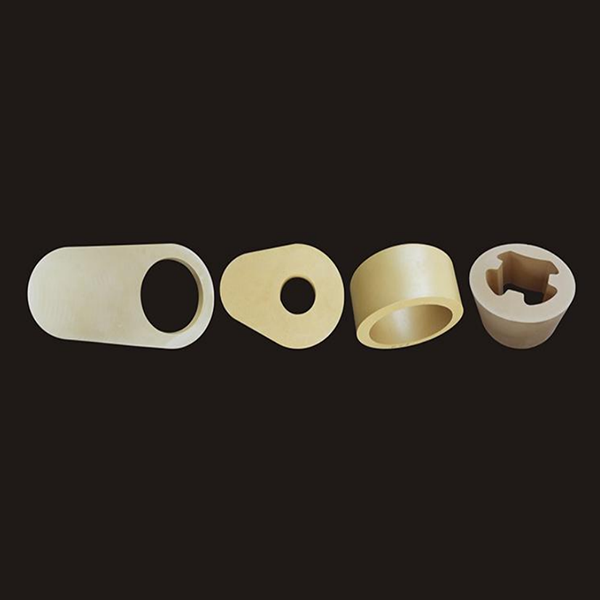

3.Metal powder, Ti series powder sintered.

Excellent chemical erosion resistance and high temperature resistance. It is resistant to erosion by various metal oxide/non-metal oxide melt, high strength, and excellent thermal shock resistance. No chemical reaction and adhesion with the ceramic components to be fired, which can ensure the stability and consistency of the performance of electronic ceramic products and improve the qualification rate of the fired products.

Translated with www.DeepL.com/Translator (free version)

Incredible Numbers

We design and produce composite thermal field for Kyropoulos Way 120kgs Sapphire Ingot by ourselves.

1,095

Service life

Super long service life of up to three years

18,000

Save energy

18,000 degrees of energy saving per seeding of 1g of crystals

2,650

High temperature resistance

Long working temperature of YZO-ZrO2 series products is 2370-2650℃ in the air,Water vapor, nitrogen and vacuum environments.

Ready for a new

Business Adventure?

Product detail pictures:

Related Product Guide:

We can constantly satisfy our respected customers with our good high quality, good price tag and good support due to we have been additional specialist and extra hard-working and do it in cost-effective way for Hot sale Zenostar Zirconia - Metal Powder/Ti Series Powder Sintering Gasket – FunMeet , The product will supply to all over the world, such as: European, Lahore, America, Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to provide more quality products and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!