OEM Factory for Aesthetic Zirconia - High Zircon Brick – FunMeet

OEM Factory for Aesthetic Zirconia - High Zircon Brick – FunMeet Detail:

Fused zirconia corundum brick is made of pure aluminum oxide powder with about 65% zirconia and 34% silica Zircon sand is a white solid formed by melting in the electric melting furnace and cooling in the model. Its Lithofacies structure is composed of eutectoid and glass phase of corundum and zirconia clinopyrite. From the perspective of facies, it is the eutectoid of corundum phase and zirconia clinopyrite phase, and the glass phase is filled between their crystals. Due to the existence of its glass phase, under the condition of long-term constant high temperature operation, the glass phase reacts and washes with some substances in the glass liquid, resulting in the loss of liquid-phase scouring and adhesion of the glass phase, resulting in the opening of porosity, and the erosion and scouring between corundum and zirconia clinopyrite by solution and low solution, resulting in the intensification of brick damage, Corundum and oblique zircon are continuously lost and lost in the glass solution with erosion and erosion. When the erosion and erosion reach a certain degree (or erosion caused by high-temperature active chemical reaction), it is necessary to stop production and replace new furnace pool electric melting bricks, which not only has high cost, but also has huge loss of shutdown and maintenance, resulting in huge cost difficulties for glass products manufacturing enterprises.

The corrosion resistance and erosion resistance of the working layer in contact with the glass solution are improved due to the increase of zirconia content, and the service life of the composite brick is correspondingly prolonged. Combined with the safety protection performance of the protective layer and the heat loss reduction performance of the thermal insulation layer, the service life of the kiln using the brick is bound to be improved, The improvement of service life means that the energy consumption is reduced, and the working layer is made of appropriate zirconium based solid solution according to different glass solutions, which can be made of different zirconium based solid solution materials for glasses with different element contents, so as to improve the wide applicability.

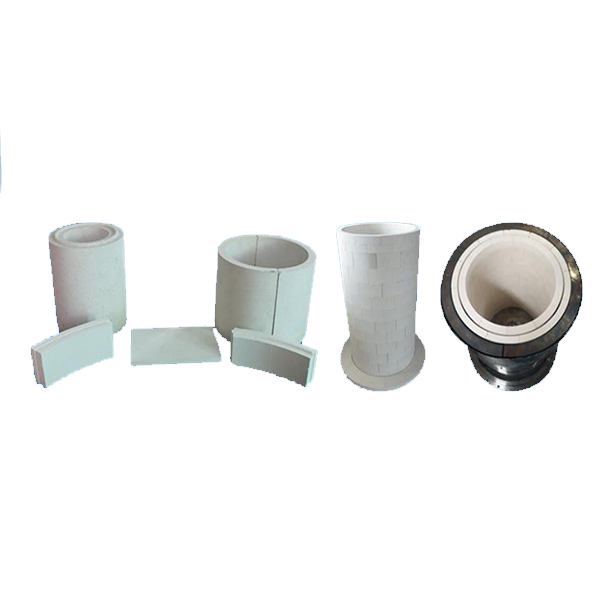

Product detail pictures:

Related Product Guide:

All we do is often involved with our tenet " Purchaser to start with, Rely on initially, devoting over the food stuff packaging and environmental defense for OEM Factory for Aesthetic Zirconia - High Zircon Brick – FunMeet , The product will supply to all over the world, such as: Cape Town, US, Johor, To work with an excellent items manufacturer, our company is your best choice. Warmly welcome you and opening up the boundaries of communication. We are the ideal partner of your business development and look forward to your sincere cooperation.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.