OEM Factory for Din Standard For Tolerance - Metal Powder/Ti Series Powder Sintering Gasket – FunMeet

OEM Factory for Din Standard For Tolerance - Metal Powder/Ti Series Powder Sintering Gasket – FunMeet Detail:

Electronic Component substrates

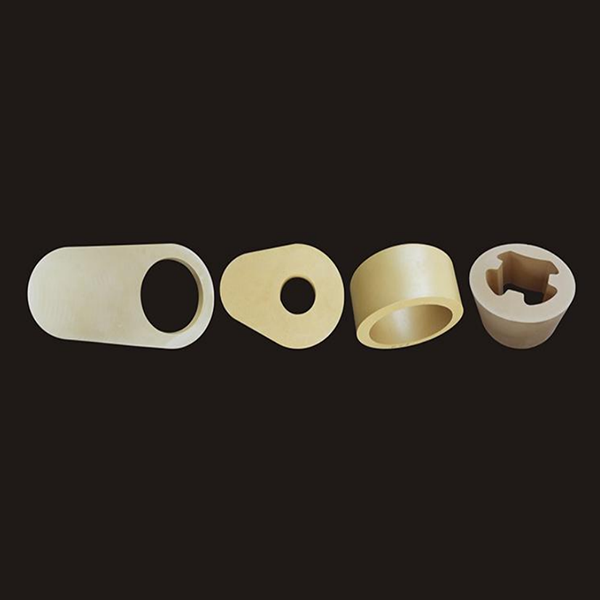

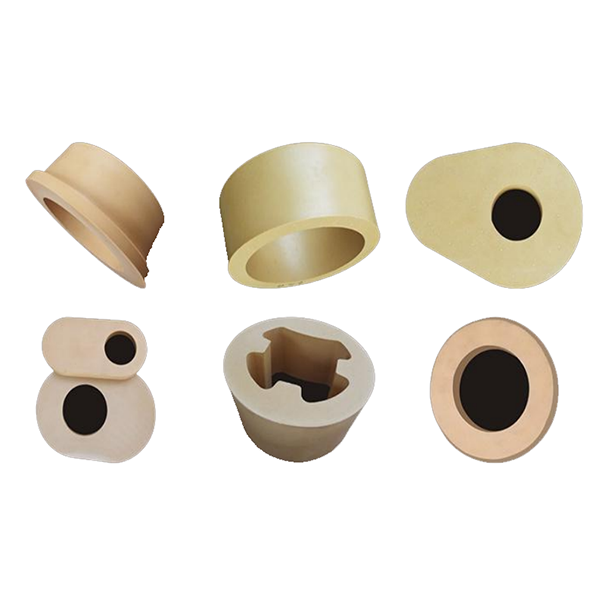

Our products are taking super high temperature composite ceramic raw material, through scientific grain gradation, mixing and grinding ,vibrating pressing, high temp. sintering etc. advanced technology and process finished. They have high-temp resisting,stable chemical performance, excellent thermal shock stability, non- wetting and adhered, easy operating, longer-working life etc. Features. Y203-ZrO2 composite and HP Y2O3 ceramic qualities are what we are usually supplying.

Application

1.Capacitor etc. Electronic component substrate sintered.

2.Barium Titanate,Magnetic material sintered.

3.Metal powder, Ti series powder sintered.

Detail

The utility model discloses a convenient metering reaction kettle for zirconia production, which comprises a kettle body, a gravity sensor, a motor, a water pump and a display screen. The bottom of the kettle body is fixed with a bottom, and the interior of the bottom is installed with a gravity sensor. The motor is fixedly installed above the kettle body, the left and right sides of the kettle body are installed with feed ports, and the lower part of the motor is fixed with a rotating shaft, The water pump is fixedly installed on the left side of the kettle body, one end of the water pump is connected with the water collecting ring through a water guide pipe, the surface of the kettle body is fixedly installed with an observation window, the lower part of the kettle body is fixedly installed with a display screen, and the surface of the water collecting ring is provided with a water outlet, The zirconia reactant above the bottom can be measured and weighed by the gravity sensor inside the bottom, which is convenient to measure the output of zirconia and improve the use effect of the reactor.

Tundish nozzle with embedded the PMO1 high performance ZrO2 Ceramic insert produced by Fangming New Materiral have the super high purity, strong chemical stability at high temperature state, high strength, strong crushing, erosion, thermal shock resisting features, low speed of diameter enlargement, extremely increased the working life of the tundish nozzle Based on the different smelt steel types in tundish and different working conditions of the different tundish nozzles, the working life of the ZrO2 upper nozzle insert, quick-changed nozzle insert, metering nozzle insert produced by Fangming New Material is 6-40hours at continuously working state.

Product detail pictures:

Related Product Guide:

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for OEM Factory for Din Standard For Tolerance - Metal Powder/Ti Series Powder Sintering Gasket – FunMeet , The product will supply to all over the world, such as: Latvia, Johannesburg, Mexico, Our solutions are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we now have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.