OEM manufacturer Special Materials For High Temperature Applications - PromotedZirconiaSlidePlate, Ring – FunMeet

OEM manufacturer Special Materials For High Temperature Applications - PromotedZirconiaSlidePlate, Ring – FunMeet Detail:

Detail

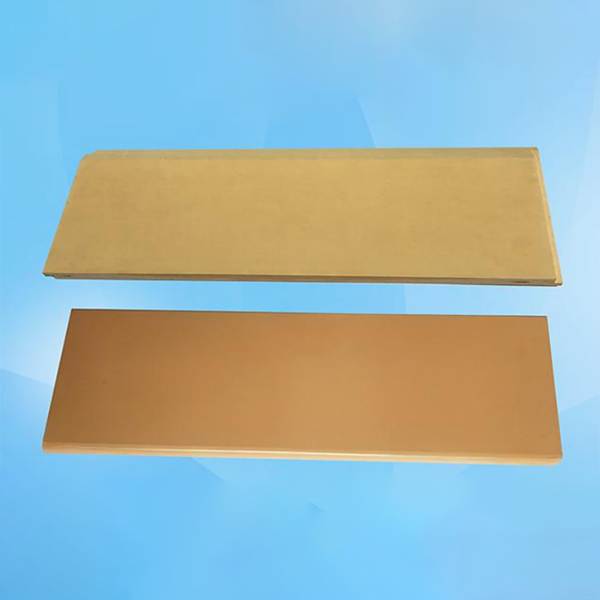

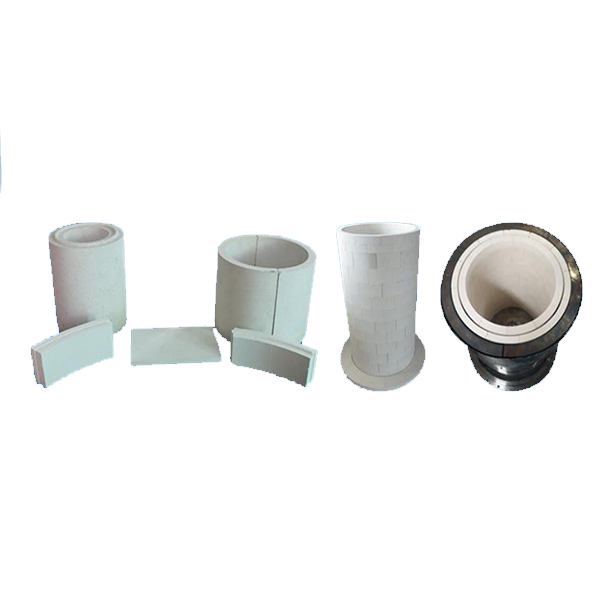

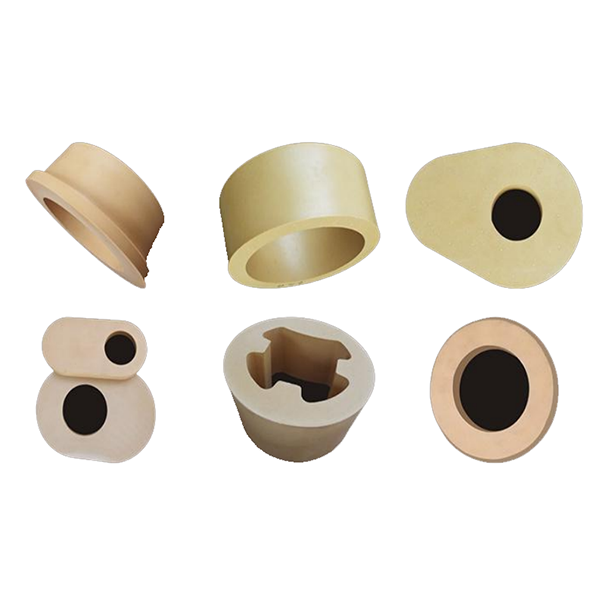

PMO1& PMD Promoted Zro2 Slide Gate Plate, Ring, Inset.

Our HP& HD PMO1&PMD products have high purity and density, excellent crush, erosion resistance and thermal shock stability, increase the working times of slige gate plates and accessory products.

In order to improve the product quality of ZrO2 sliding plate containing MgO and improve its service life on converter, the microstructure photos with magnification of 10000 ~ 100000 times were taken. The microstructure and corrosion mechanism of the product before and after use were investigated by fesem-eds. the results show that the main crystal phases are strip woven c-ZrO2 and granular m-ZrO2 crystal, A small amount of M2S and other cemented phases are generated between the crystals. The used sliding plate has a segmental structure. The eutectoid phase transformation of ZrO2 occurs in the reaction zone and a series of reaction products are generated, such as CaZrO3, FeO, spinel, silicate, etc. the damage of the sliding plate is mainly the erosion of slag.

Different steel types, different working temp. of steel liquid, different liquid flowing amount and speeds will influence of working lives of slide gate plate.

In view of the shortcomings of ordinary aluminum carbon sliding plate, such as low strength, poor corrosion resistance and poor thermal shock resistance, experimental research is carried out from the aspects of material, micro powder additives and production technology. Based on ordinary aluminum carbon sliding plate, an aluminum carbon zirconium composite sliding plate with excellent performance is developed, which meets the service requirements of continuous casting 160t ladle for three times at Pangang.

Adopt composite slide gate plate with embedded our HP&HD Zro2 inserts is the direction and mainstream of steel-melting development with converter in the future.

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict quality control, reasonable price, superior service and close co-operation with customers, we are devoted to providing the best value for our customers for OEM manufacturer Special Materials For High Temperature Applications - PromotedZirconiaSlidePlate, Ring – FunMeet , The product will supply to all over the world, such as: Oman, Iran, US, Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to provide more quality products and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.