OEM/ODM Manufacturer Coefficient Of Thermal Expansion Silicon Carbide - ZirconiaSlidePlate,Ring(PMDQuality) – FunMeet

OEM/ODM Manufacturer Coefficient Of Thermal Expansion Silicon Carbide - ZirconiaSlidePlate,Ring(PMDQuality) – FunMeet Detail:

Detail

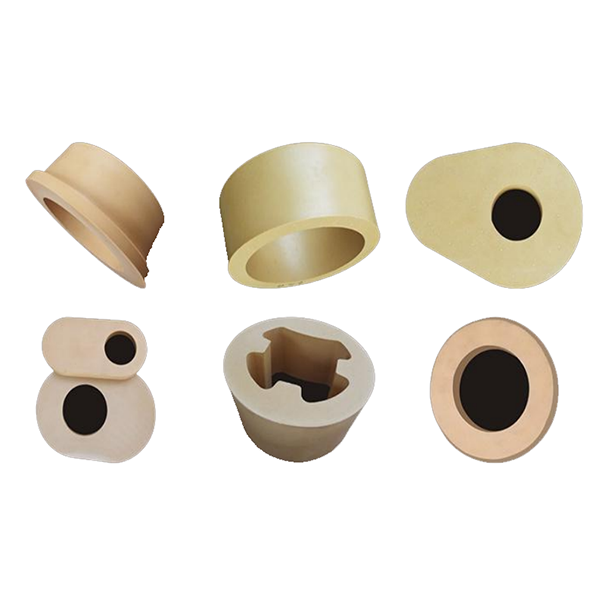

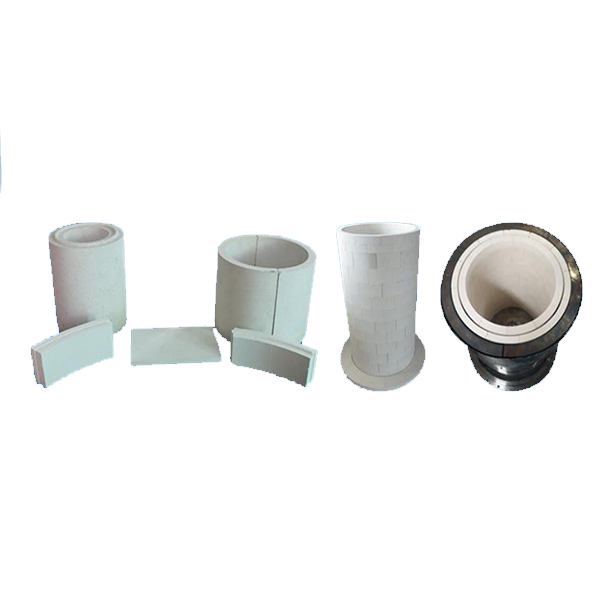

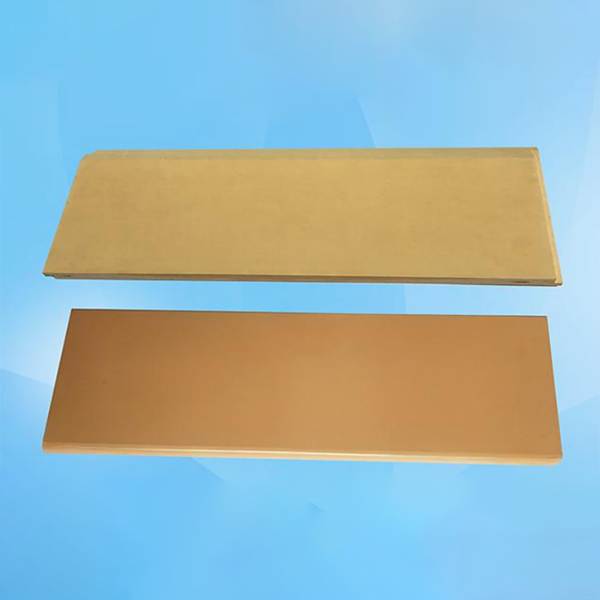

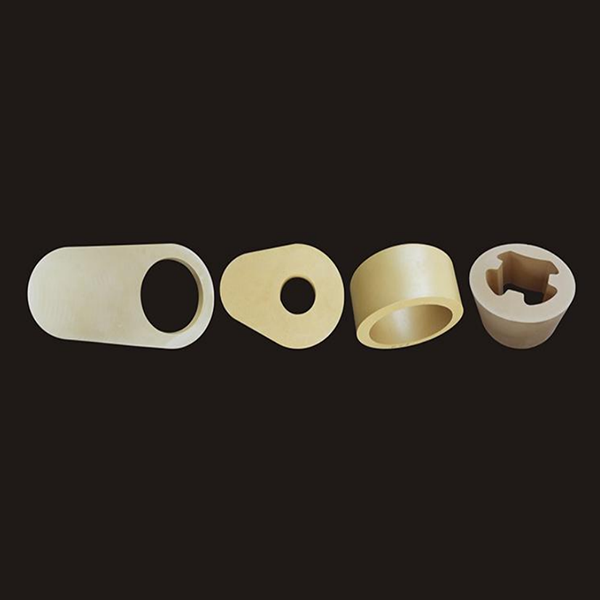

PMD Series Zro2 Composite Ceramic Slide Plate, Zro2 Ring, Insert

A combination of Raman data with thermogravimetric analysis (TGA) results prove that grafting of organic macromolecules onto ceramic surfaces takes place. Dynamic mechanical analysis (DMA) has been performed from 100 to +50°C; addition of the ceramic increases the storage modulus ′, more so for modified filler. Compared to PP and thermoplastic vulcanizate (TPV), a higher thermal expansion is seen after addition of the ceramic filler, a result of creation of more free volume. The tensile modulus of the composites is about 1.2 times that of pure TPV, an increase in the rigidity clearly caused by the ceramic. Fracture surfaces show weak bonding of filler particles to the matrix. In the sample containing modified filler the tensile deformation is going through the polymer matrix.

A ceramic composite is able to whithstand temperatures in excess of 2200 F on a repeated basis without cracking due to thermal shock. The composite has a web of reinforcement fibers; and a matrix that substantially the web after the firing step. The matrix is formed around the web by impregnating the web with a sol containing alumina and, in some cases, rare earth oxides, and firing the composite after the impregnation. The web may be a three-dimensional orthogonal weave of the reinforcement fibers, where the fibers are a transitional phase alumina. The composite is essentially free of Group I and Group II metals and transition metal oxides. The composite may be used as a refractory brick or lining and may also be used as an insulatingmaterial due to its chemically non-reactive nature.

Product detail pictures:

Related Product Guide:

No matter new customer or previous client, We believe in prolonged time period and trustworthy relationship for OEM/ODM Manufacturer Coefficient Of Thermal Expansion Silicon Carbide - ZirconiaSlidePlate,Ring(PMDQuality) – FunMeet , The product will supply to all over the world, such as: Canada, Mongolia, Sevilla, Our products are mainly exported to Southeast Asia, the Middle East, North America and Europe. Our quality is surely guaranteed. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!