Top Suppliers Ceramic Electrical Insulators - Metal Powder/Ti Series Powder Sintering Gasket – FunMeet

Top Suppliers Ceramic Electrical Insulators - Metal Powder/Ti Series Powder Sintering Gasket – FunMeet Detail:

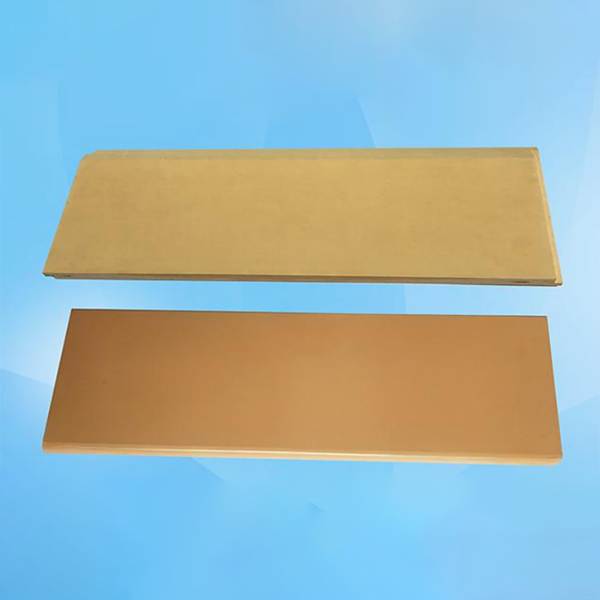

Electronic Component substrates

Our products are taking super high temperature composite ceramic raw material, through scientific grain gradation, mixing and grinding ,vibrating pressing, high temp. sintering etc. advanced technology and process finished. They have high-temp resisting,stable chemical performance, excellent thermal shock stability, non- wetting and adhered, easy operating, longer-working life etc. Features. Y203-ZrO2 composite and HP Y2O3 ceramic qualities are what we are usually supplying.

Application

1.Capacitor etc. Electronic component substrate sintered.

2.Barium Titanate,Magnetic material sintered.

3.Metal powder, Ti series powder sintered.

Detail

The utility model discloses a convenient metering reaction kettle for zirconia production, which comprises a kettle body, a gravity sensor, a motor, a water pump and a display screen. The bottom of the kettle body is fixed with a bottom, and the interior of the bottom is installed with a gravity sensor. The motor is fixedly installed above the kettle body, the left and right sides of the kettle body are installed with feed ports, and the lower part of the motor is fixed with a rotating shaft, The water pump is fixedly installed on the left side of the kettle body, one end of the water pump is connected with the water collecting ring through a water guide pipe, the surface of the kettle body is fixedly installed with an observation window, the lower part of the kettle body is fixedly installed with a display screen, and the surface of the water collecting ring is provided with a water outlet, The zirconia reactant above the bottom can be measured and weighed by the gravity sensor inside the bottom, which is convenient to measure the output of zirconia and improve the use effect of the reactor.

Tundish nozzle with embedded the PMO1 high performance ZrO2 Ceramic insert produced by Fangming New Materiral have the super high purity, strong chemical stability at high temperature state, high strength, strong crushing, erosion, thermal shock resisting features, low speed of diameter enlargement, extremely increased the working life of the tundish nozzle Based on the different smelt steel types in tundish and different working conditions of the different tundish nozzles, the working life of the ZrO2 upper nozzle insert, quick-changed nozzle insert, metering nozzle insert produced by Fangming New Material is 6-40hours at continuously working state.

Product detail pictures:

Related Product Guide:

We hold strengthening and perfecting our items and repair. At the same time, we get the job done actively to do research and progress for Top Suppliers Ceramic Electrical Insulators - Metal Powder/Ti Series Powder Sintering Gasket – FunMeet , The product will supply to all over the world, such as: Lesotho, Uganda, Johannesburg, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, please feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our products, please feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.